In today's globalized environment, whether it is dealing with complex situations such as industrial pollution, virus transmission, or chemical leakage, the importance of personal protective equipment has become increasingly prominent. Among them, FFP3 level dust masks have become the first choice protective tool for high-risk professionals and special environments due to their excellent filtration performance and comfortable design. The following will briefly analyze the advantages, market positioning and production process of FFP3 masks.

1. Characteristics and advantages of FFP3 level masks

Ultra-high particle filtration efficiency

The core advantage of FFP3 level masks lies in their ultra-high filtration efficiency. According to the European standard EN 149:2001+A1:2009, FFP3 masks must be able to filter out at least 99% of non-oil and oily particles in the air, including but not limited to dust, smoke, bacteria and virus particles, thereby providing the wearer with A near-perfect protective respiratory barrier.

Safe and reliable design

This type of mask uses multi-layer filtration technology, combined with efficient electrostatic filter material, to achieve high-efficiency filtration without affecting breathability. In addition, the design that fits the face closely ensures that harmful external particles cannot bypass the mask and directly enter the respiratory tract, greatly reducing the risk of infection or inhalation of toxic substances.

Balance comfort and durability

Although FFP3 masks have strict protection standards, they are also designed to pay attention to the wearer's comfort experience. The soft material and ergonomic structure ensure that there will be no pressure or allergic reaction when worn for a long time. The high-quality elastic straps and adjustable nose clip enable the mask to stably fit various face shapes, which not only improves the sealing effect but also enhances durability.

2. Market positioning and application fields

FFP3 level masks are positioned as high-end professional-grade protective products in the market due to their unparalleled filtration capabilities. Widely used in the following fields:

·Medical industry: operating rooms, infectious disease isolation areas and other places that require extremely high cleanliness.

·Chemical industry: working environment where hazardous chemicals and radioactive dust are handled.

·Pharmaceutical industry: a key link in preventing microbial contamination during drug production.

·Mineral mining: Avoid inhaling silica dust and other mineral dust in coal mines and metal mines.

·Laboratory research: Operations are conducted in laboratories with higher biosafety levels.

3. Production technology and manufacturing difficulties

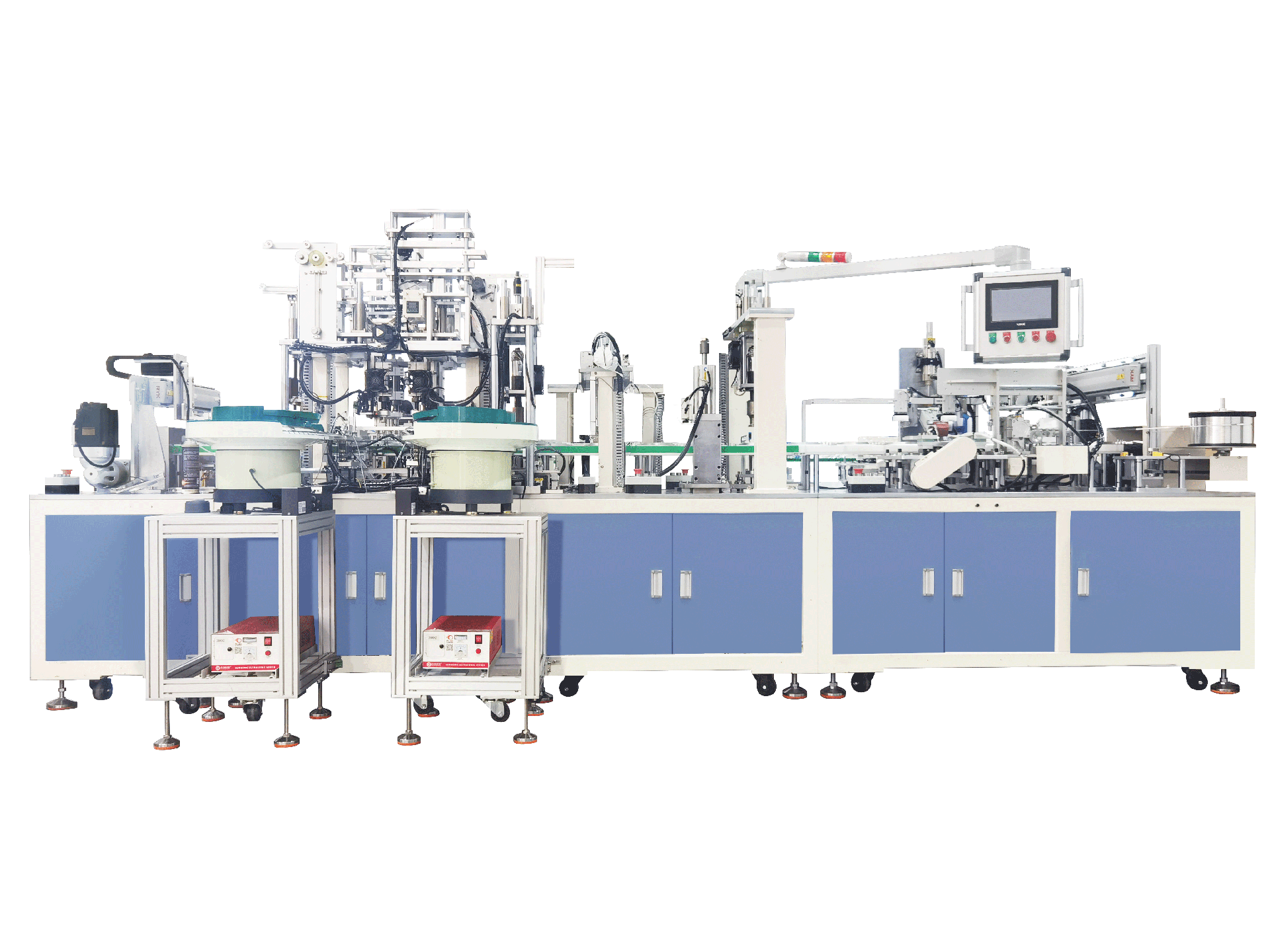

Producing FFP3-level masks is a technology-intensive task that involves precise material selection, advanced production equipment, and strict quality control systems. Core challenges include:

·Material R&D: Develop filter media with high efficiency and low resistance characteristics while maintaining good comfort.

·Molding accuracy: To ensure that the shape of the mask accurately fits different face shapes, improve sealing, and reduce air leakage, this requires precise control of the equipment process.

·Quality inspection: Each finished product must undergo rigorous testing to confirm that it meets the FFP3 standard filtration efficiency and leakage rate indicators.

With the advancement of technology and the growth of market demand, FFP3 level masks are gradually realizing automation to overcome production problems and move toward a wider civilian market. However, its high cost and complex manufacturing process also mean that such products will still focus on the needs of professional fields and specific high-risk groups in the short term.